So you want to save some additional dough, and do your next brake job yourself, but the bleeding process still seems a tad daunting. Well, worry no more, good citizen! We teamed up with the guys over at Performance Online (POL) and have created a duo of useful how-to videos on brake bleeding to help show you how it’s done. Being that some of you prefer a written rundown as well, we caught up with JC Genty from POL in order to go over a few of the more crucial portions of brake bleeding, and the reasoning behind these techniques.

In its simplest form, bleeding removes air bubbles from a vehicle’s brake system, in the process firming-up pedal-feel, and guaranteeing that you stop in a tidy fashion. When asked what might happen if a brake system is not bled after, say, fresh pads and shoes are installed, JC laughs and says, “The tree in front of you will become a part of you!” A humorous, yet unnervingly true statement on the matter.

JC explains that air compresses much easier under pressure, whereas fluid does not, so in order to brake safely, there cannot be any pockets of air within the brake system. So if your pedal suddenly stops offering a lot of resistance, or goes to the floor, watch out! Chances are you’ve got air in your lines somewhere and it needs to be removed in the proper method with appropriate tools. Brake bleeding tools are simple, inexpensive, and effective; just be sure to spend the money and get one with lines, caps, nozzles, fill bottles, and cut-off valves for easy use.

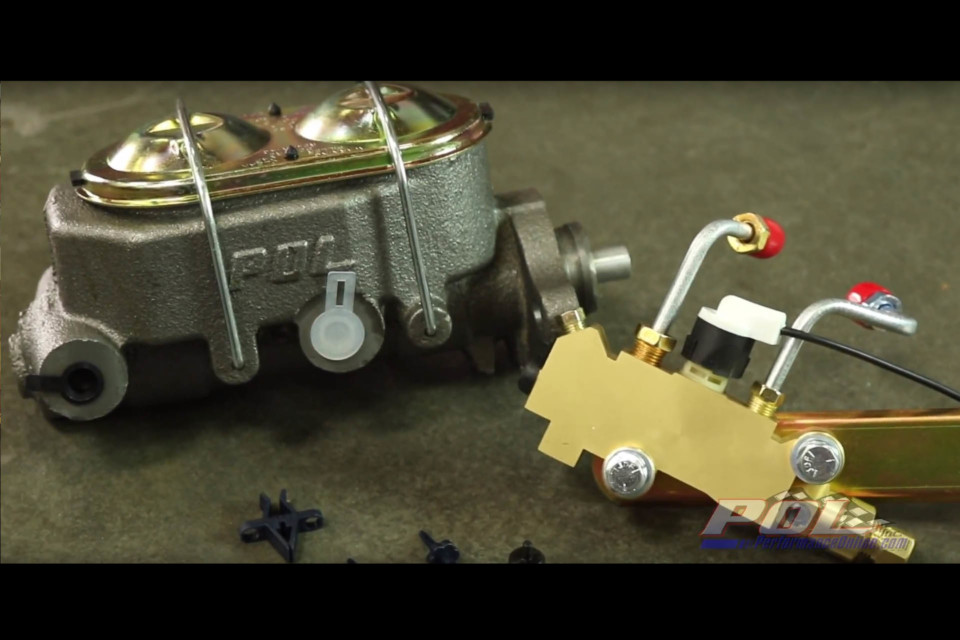

Step 1: Bench Bleed the Master Cylinder

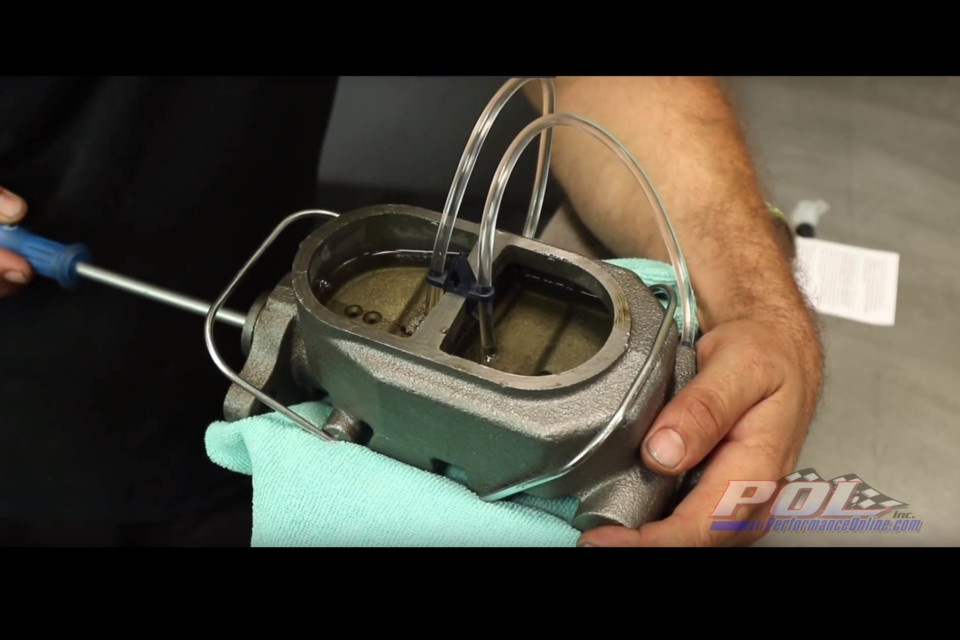

As the video illustrates, after properly securing the master cylinder in a vice and filling it with the DOT-approved fluid that matches the vehicle, it’s important to make sure that the cylinder remains completely level. From there, you can begin attaching bleeder hoses and nozzles. On older vehicles, you will probably need to utilize two hoses, one for each reservoir bowl, whereas newer models will likely only require one hose for circulating fluid between the reservoir and the orifice.

After the ports are plugged with the bleeding kit’s tapered nozzles and the reservoir is filled with fluid, you can start slowly pumping the master cylinder’s piston with a large screwdriver. Avoid fast strokes, for this will aerate the fluid, forcing you to start all over again. Once the hose ends are not generating any more bubbles, you are officially done with the master cylinder’s bench bleeding step, and are now ready for install. Just make sure that you attach the reservoir cap and keep those port holes and hose ends plugged, as brake fluid is notorious for destroying paint.

Once installed, with brake lines attached to the master cylinder, have someone climb inside and hold the brake pedal firmly while you loosen one line at a time in order to remove any trapped air that might still be lingering in the system. From there, it’s on to bleeding each corner of the vehicle, bringing you one step closer to superior stopping power!

Step 2: Individually Bleed Each Corner of the Vehicle

With the master cylinder properly bled, it’s time to rope in a friend in order to help with the final round of brake bleeding, as there needs to be someone within the vehicle who can press the brake pedal while you bleed each corner. Materials needed for this portion include a wrench for opening the bleeder screws, a bottle for catching the fluid, and a tube that can fit over the end of the bleeder screw and run to said container. If you plan on buying a brake bleeding kit, make sure it comes with these items, for they will help with bench bleeding stage as well.

JC explains that bleeding the corner furthest away from the master cylinder should always be done first since that’s the longest “push” for the system, subsequently making the bleeding process that much easier due to removing the majority of the pressure first. Starting with the most difficult corner also means the system will be far less susceptible to developing additional air bubbles, a headache that will force you to start over.

With the car off the ground and supported by jack stands, wheels removed, and penetrating oil sprayed on each loosened bleeding screw, re-tighten each screw and make sure that the brake reservoir is topped-off. Then, with the tube firmly attached to the bleeder screw, and the fill bottle raised above the caliper or drum, have your assistant press and hold the brake pedal down and notify you once they are applying pressure. Crack open the bleeder screw until a steady stream of fluid and air can be seen entering the tube.

With the bleeder open, the brake pedal will travel downward toward the floorboard, at which point your assistant should shout “Floor!” so that you know to cut off the flow of fluid going into the tube and check the reservoir level, topping it off as necessary. Repeat these steps until there is no more air to be seen in the lines. From there, you can move on to the other corners of the vehicle, repeating these steps along the way, until all of the air has been removed from each line.

Finally, with the master cylinder reservoir cap removed, have your assistant give the brake pedal a few abrupt pushes. A violent eruption of fluid will let you know that there is still air in the lines, whereas a mild disturbance signals a properly bled system. After double-checking that each bleeder screw is tight, you can then reattach the reservoir cover, install the vehicle’s wheels and tires, and take it out for a test spin. The pedal should feel firm and stopping distances should be consistent and tidy. Any unexpected pedal travel or stopping issues mean that you need to check the system once more for bubbles, or that there is another issue at foot that needs to be addressed.