You’re drivin’ along, you’re drivin’ along, soaking up the whoops and doing 70 miles an hour as your friends record you from the highway. Things are going alright and your buddies are cheering you on as you mob your way through the up-and-down terrain along the San Felipe highway. You’ve done this a few times now and know what’s coming around the corner, long before it’s there.

Everyone is having a good time, and then the guys start gesturing “hammer down” as they speed away, hoping you’ll get the message. You do, and start picking up momentum, the whoops becoming more and more frequent and violent. This is the thrill, being right on the edge, and it feels amazing until – SNAP – it happens.

By some miracle, the truck came to a stop without flipping as you veered onto the highway, metal scraping loudly against the asphalt, the wheel barely holding on. The damage is rampant and will take a while to fix it back together again. But back home, you’re in your element as you take a look at the wheel well and find the critical failure that started it all – the upper ball joint.

This story is a tale as old as time in off-roading, and was what led to the introduction of spherical bearings (or uniballs, as they’re sometimes called) in the hobby. FK Rod Ends has had decades of experience in manufacturing these bearings. They talked with us and expanded our understanding of the small yet invaluable ball-and-socket component.

Small And Tough

Our contact at FK Rod Ends was Jay Langley, a fellow off-road enthusiast whose understanding of the hobby made it easier to comprehend the ins and outs of FK’s spherical bearings. He explained, “In a nutshell, spherical bearings are used in suspension to allow for greater strength and movement – as in, increased pivoting angles – in addition to better control, less deflection, and more positive input to steering, braking, and acceleration. They are also used in any place where movement is needed.”

Movement is, of course, happening all over a given truck as it’s off-roading; shocks are compressing and drooping, transmission gears are shifting back and forth, and so on. But Langley clarified: “Spherical bearings spend life in controlled motion. That is, any area where motion is important. On vehicles, they are used in place of ball joints on control arms, sway bars, tie rod ends, and on linked systems to replace rubber, urethane, or other soft sound or motion-absorbing joints.”

But what distinguishes the spherical bearing from a ball joint? If the OEMs put them in the vehicle, they must be good enough for anything, right? Wrong – at least where it concerns off-roading. The nature of ball joints makes them versatile, true, but they are ill-suited for the specialized abuse of constant terrain changes.

“Ball joints have a couple of things going against them when you’re off-roading,” said Langley. “First, they usually contain some form of grease for lubrication. The grease actually causes premature wear on the rubber, and will catch and spread contaminants, speeding up its failure point. Second, they are usually made by OEMs, and even then are regarded as inexpensive, all-purpose rotating joints.”

Meanwhile, an FK Rod Ends spherical bearing can meet the challenge of off-pavement abuse, and persevere. Stainless steel, heat treating, and a PTFE liner go a long way toward overall strength and reliability. Now that we know the better option that is the spherical bearing, we can dive a little deeper and explore what sets FK Rod Ends’ units apart.

FK Rod Ends Distinguishing Features

It’s no secret that even within the realm of spherical bearings, the customer has many options. Some of them might include the ones found on sites like eBay. However, not all bearings are alike, and in the case of FK Rod Ends, the dedication to quality is much higher than low-level competitors.

All of FK Rod Ends’ products are made in the United States. Their manufacturing facility is in Southington, Connecticut.

“A favorite saying of mine goes, ‘quality is remembered long after price is forgotten,'” said Langley. “FK Rod Ends builds its products in the USA, and while we do import some product to cater to the entry-level customers, it can’t compare to the homemade product. For instance, our KMX line is imported and is a great product, but it is far less capable than the JMX line. Our competitors try to use a KMX-like product to compete against the JMX, and that is their downfall.”

“The JMX uses American-sourced metal, and is a three-piece design, which allows us to get the greatest strength because we can control all of the processes along the way – treat it, chromate it, et cetera. Plus, it’s made with American machines, and is used and proven in American race vehicles,” continued Langley. “The PTFE is installed in a multi-step process and performs without evaporating at high temperatures or seizing up when frozen. What’s more, its coefficient of friction decreases at high loads.”

“It’s also bonded by human hands to the bearing race, rather than by a machine,” added Langley. The fabric also performs as a wiper keeping contaminants from the bearing surface, and it’s built to withstand the abuse that extreme motorsports requires.”

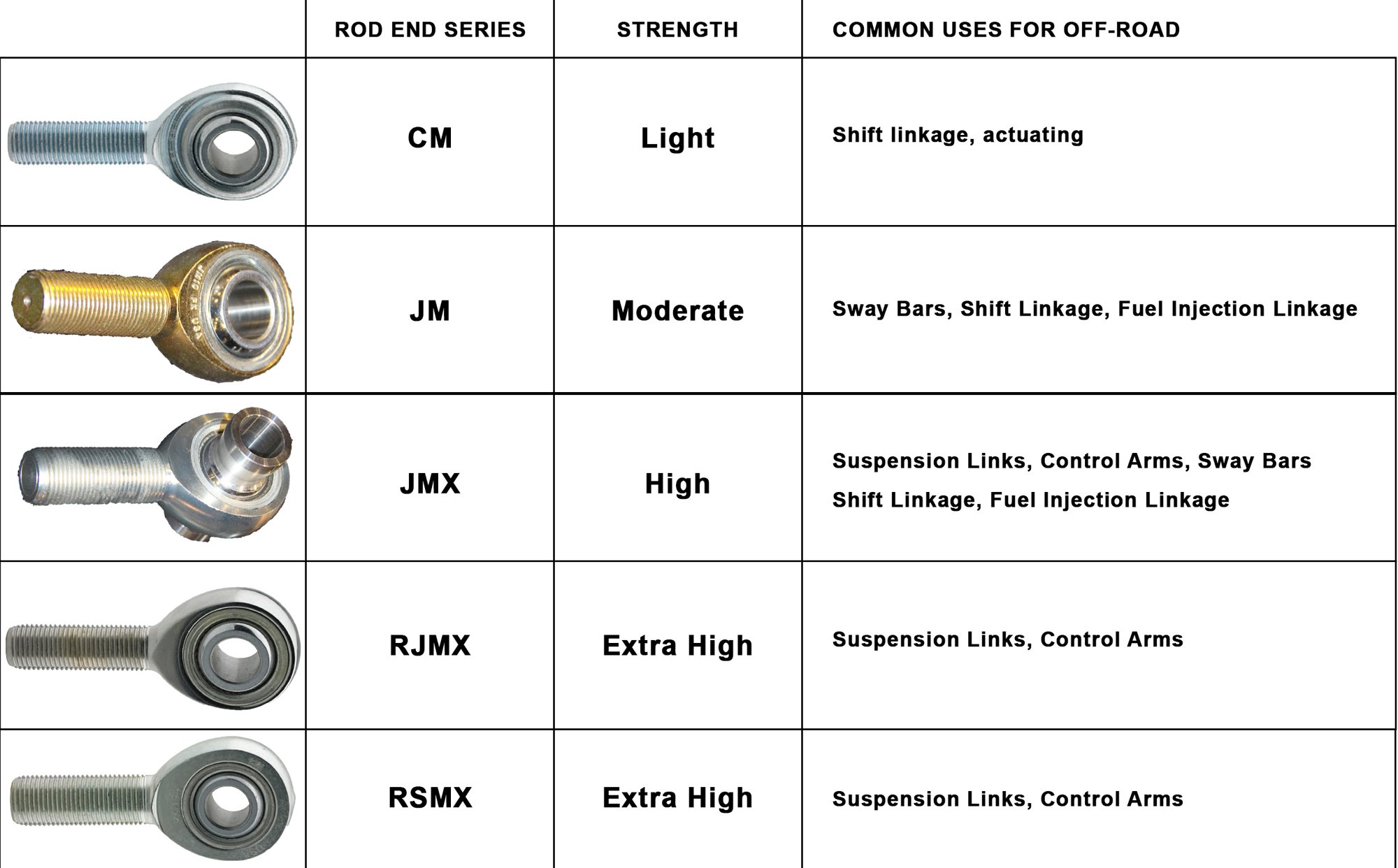

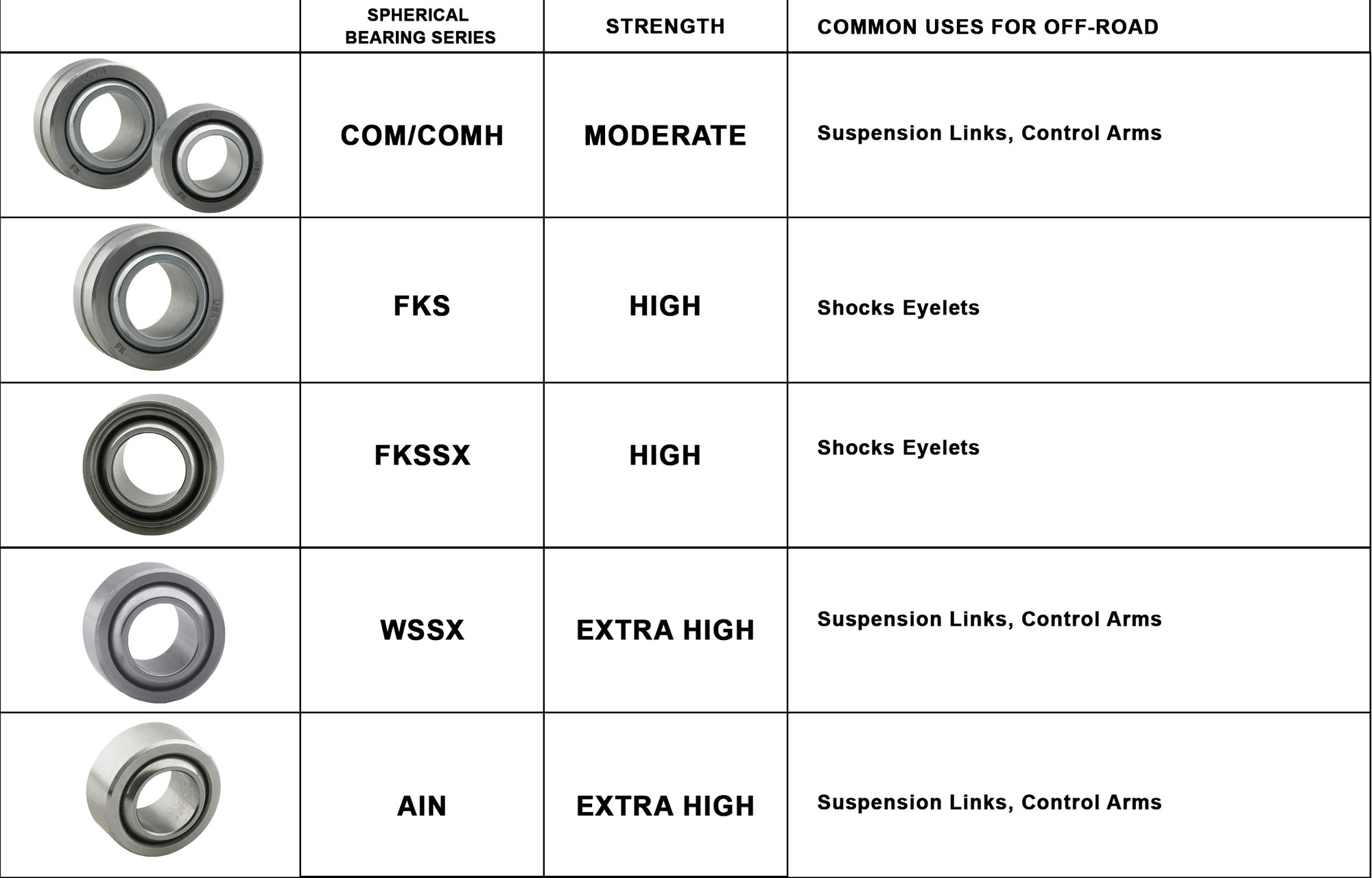

These handy charts explain a handful of rod end and spherical bearing information, including series, strengths, and popular uses in off-road.

Langley wants both racers and weekend warriors to think a little more about it this way: “Shouldn’t we do our due diligence and ensure we have the right product for the right purpose? Consider this when you are getting ready to buy a set of spherical bearings or rod ends.”

Fitments Of Spherical Bearings

FK Rod Ends manufactures a wide array of spherical bearings for a wide array of vehicles. You can see the 10 distinct series on FK’s website, but we are more interested in going over the process of their construction and features.

Another facet of spherical bearings is their fitting into the socket. This is an incredibly important process, since it lays the foundation for how the bearing will perform under stress, as well as the amount of play they can exercise. “We make our spherical bearings to a positive nor negative tolerance depending on an exact part number,” explained Langley. “For example, our CP cups fit our bearings using a transitional fit; it’s not a slip fit nor a press fit, but right in between. A snap ring secures the bearing the cup and ensures positive placement.”

“Sometimes, because of tolerances being positive on one part and negative on the other, we can end up with a near-slip fit or near-press fit,” continued Langley. “But the point is always to make the assembly easy while keeping the noise to a minimum. Slip fits can cause popping or clicking, as well as wear, while press fits need new cups for every replacement. Therefore, transitional fits are a way of solving both issues.”

Some of FK's products, like these rod ends, may look very similar. However, they offer totally different traits in terms of construction and bearing play.

Once they’re fitted into the socket, however, the ease of play in them is varied from one unit to the next. You might find a rod end has more play than a control arm, for example. “Tolerances all depend on the exact part number, some are as high as .005 inches and as low as .0005 inches. It really depends on the tolerance we are speaking about, whether it’s the outside diameter, bore diameter, or width of the part. As for looseness or tightness, when we use PTFE on a bearing, we have three levels – F1, or tight; F2, or moderate; and F3, or loose. F1 requires a levering tool to assist movement, F2 can rotate by hand with some effort, and F3 should be easily moveable by hand.”

PTFE: The Stuff Of Magic

To add another degree of separation from OEM ball joints and FK spherical bearings, FK uses polytetrafluoroethylene, better known as PTFE, and arguably even better known as “Teflon”; however, this is an oversimplification, and only serves as a mental image.

Langley offered a more educated perspective on PTFE in spherical bearings. He said, “PTFE is a dry lubricant. For off-road motorsports, it is unparalleled.”

As we learned from Langley, PTFE contrasts other lubricants in its dry state of being, where others are semi-solid or liquid-based. “Semi-solid and liquid-based lubricants attract dirt and wear quickly,” he said. “PTFE, however, being dry and slick, eliminates the attraction of dirt. In addition, PTFE manages the heat that off-road suspension systems create when being used for extended periods of time. This contrasts the other types of lubricant, which drip or burn off, leaving dirt to wear out the bearing more quickly.”

Hi, Ms. Alignment-Spacers!

Something you might have come across in checking out spherical bearings is the term “high misalignment spacer.” An add-on to rod ends, they are mainly used in off-road for their unparalleled pivot angle capability compared with ball joints, and it’s easy to see why.

“High misalignment spacers are used in spherical bearings and rod ends to increase the pivoting angle,” said Langley. “In off-road, that angle is everything. Off-road suspension systems have to do so many things at once and still maintain excellent control and driver confidence; for this reason, the high misalignment spacers has become an unsung hero.”

High-misalignment spacers, like the one on this JMX rod end, allow for a greater pivot angle on the bearing. This improves travel during high dynamic load situations.

As an example, using one of FK’s WSSX16T bearings, a user will achieve about 15 degrees of angle with a 1-inch-diameter bolt. But when the 16-12HB spacer is installed into either side of the bearing, a user gains up to 60 degrees of angle and steps down to 3/4-inch bolt. It jumps to 66 degrees of angle with a 16-10HB spacer and 5/8-inch bolt.

As you can see, the tradeoff in smaller bolt diameter and greater pivoting angle is there, but as Langley commented, “The people who engineer off-road suspension have figured this tradeoff to be well worth it.” He also pointed out that the spacer is why the old trophy trucks of the ’80s and ’90s had trouble going over bumps, while modern trophy trucks seem to glide right over them.

Keeping Spherical Bearings In Shape

Professional racers like Casey Currie know all too well the importance of good, solid bearings. Photo: Monster Energy

Once you have spherical bearings installed on a vehicle, they should prove to be less of a nuisance than ball joints. “Other than being kept free of dirt, moisture, and debris, a spherical bearing using PTFE should require little maintenance for its life,” said Langley. “A play car cleaned after each time out and stored in a dry area may go years without needing replacement bearings.”

Oddly enough, according to Langley, the problems of maintenance are more often seen on play vehicles rather than race vehicles. “Racers will do teardowns after every race and install new bearings, that’s just what they do,” he said. “But play cars just get used for play, and their owners will get complacent or ignore bearing noises and faults.”

Rod ends waiting for assembly. Photo: Thorco Racing

So if you fall into the play vehicle category and are thinking of getting spherical bearings, or already have them and haven’t checked on them in a while, Langley offered some recommendations. “Look for contaminants after every outing, as these account for most wear issues,” he said. “Also look for discoloration from heat. This usually means the tolerances have warped enough to need replacement. If the PTFE liner is popping out, then that needs immediate replacement. And lastly, if the bearing suffered a major hit, it will change the shape of the ball or race, and need immediate replacement as well.”

Rod ends and spherical bearings are two things that every serious off-road build will need at some point. One thing is for sure – no matter how soft or raging your treatment of your rig is, the terrain will find the weak point and find you limping home. Preparation and understanding your needs are key to getting the most out of off-pavement fun, and FK Rod Ends is on hand to help. Reach out to them online or by phone today, and don’t forget to follow them on Facebook.